engineering a human-habitable mars colony

By Julian Stromer, Mar 21, 2023

engineering a successful mars habitat

The purpose of my project has been to design a human habit that could successfully work on the planet Mars. Recently, I saw a video about a bunch of different designs for Mars habitats, and I thought that most of them seemed either unrealistic or totally impractical. They mostly looked like they were really pretty homes that would be hard to build here on Earth, let alone on Mars.

I was really interested in designing a Martian habitat that could actually be built on Mars, and that would be a practical place to work and live. One of the things that I immediately realized was that the only way to design a truly practical habitat would be to understand the biggest engineering challenges that would be faced. Some of these included:

Understanding the environment that the habitat would experience…

What temperatures, weather, seismology, and geology would the habitat face?

Understanding what life support would be needed…

How would the inhabitants get air, water and food? How would they dispose of waste? How would they clean themselves?

Quality of life…

What would the inhabitants need for a decent quality of life? How much space would they need? What about privacy, rest, sleep, exercise, comfort, quiet and entertainment?

Understanding these requirements, I began to think about possible structural shapes and building materials because my choices would not only have to meet the needs of the inhabitants, but would also have to either be carried to Mars on a rocket, or built on the surface of the planet.

habitat solutions that have been proposed, so far…

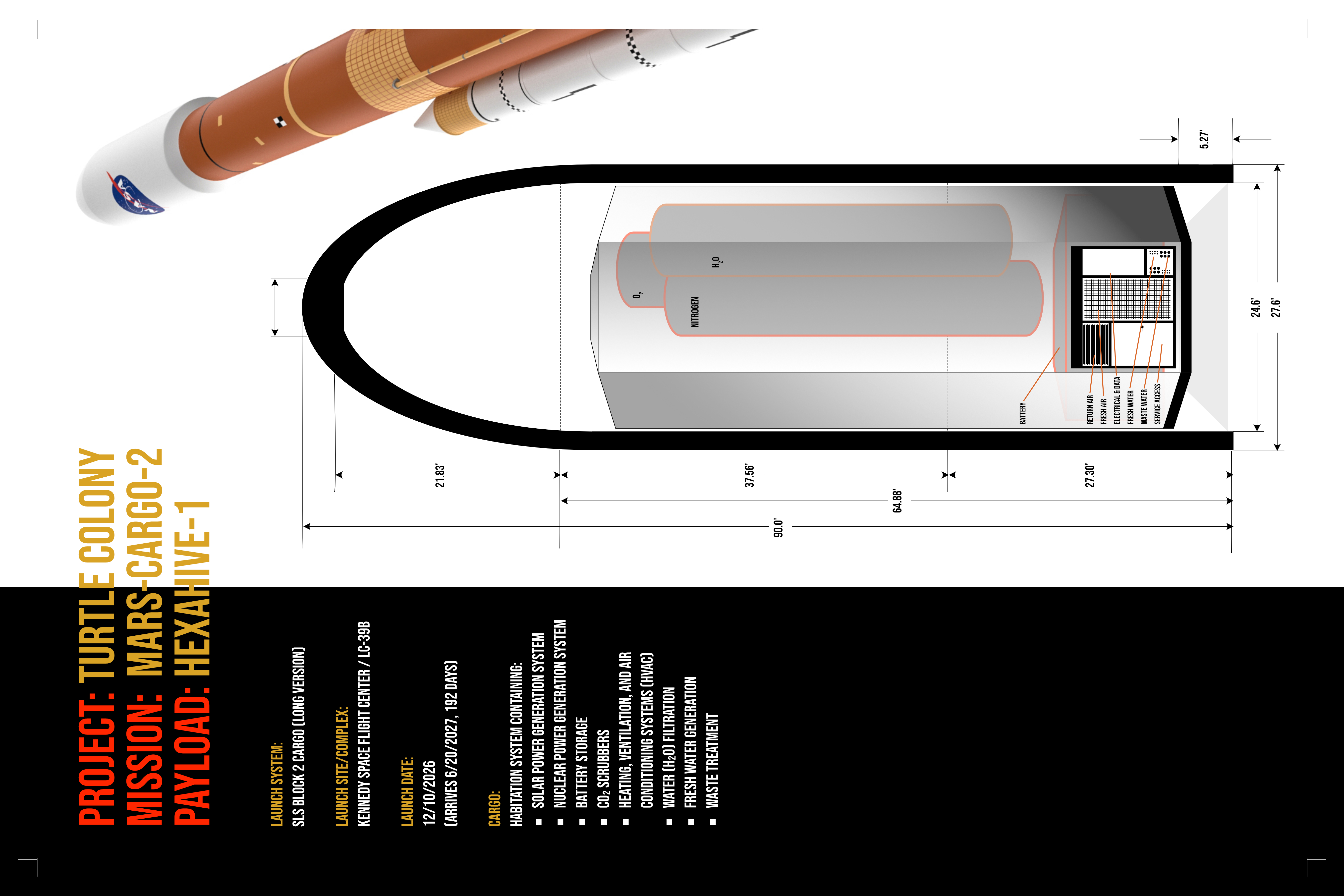

There have been many different designs and materials proposed for Mars habitats. Some are metal pods, built on Earth and carried to Mars. This is actually possible. NASA's Space Launch System, SLS, especially its latest version, called the Block 2 Cargo Long Version, has a huge interior space that is twenty-four and a half feet wide and over 65 feet high. It can carry loads of up to 101,400 pounds. However, this would mean that a separate ship would have to be sent for each structure needed on the surface of Mars. At a cost of billions to launch each one, and leaving the astronauts with no way to build more structures, this is not really the best possible option.

Another proposed solution is to send inflatable housing. This is also realistic and possible. NASA has found materials that are extremely strong, that would be able to roll up and then expand. However, these 'bubbles' would then need to be covered in material from Mars, either above ground, or by being buried under the surface, to protect the inhabitants from the Sun's radiation, from the freezing temperatures and from other weather extremes. So, a great amount of construction would still be needed.

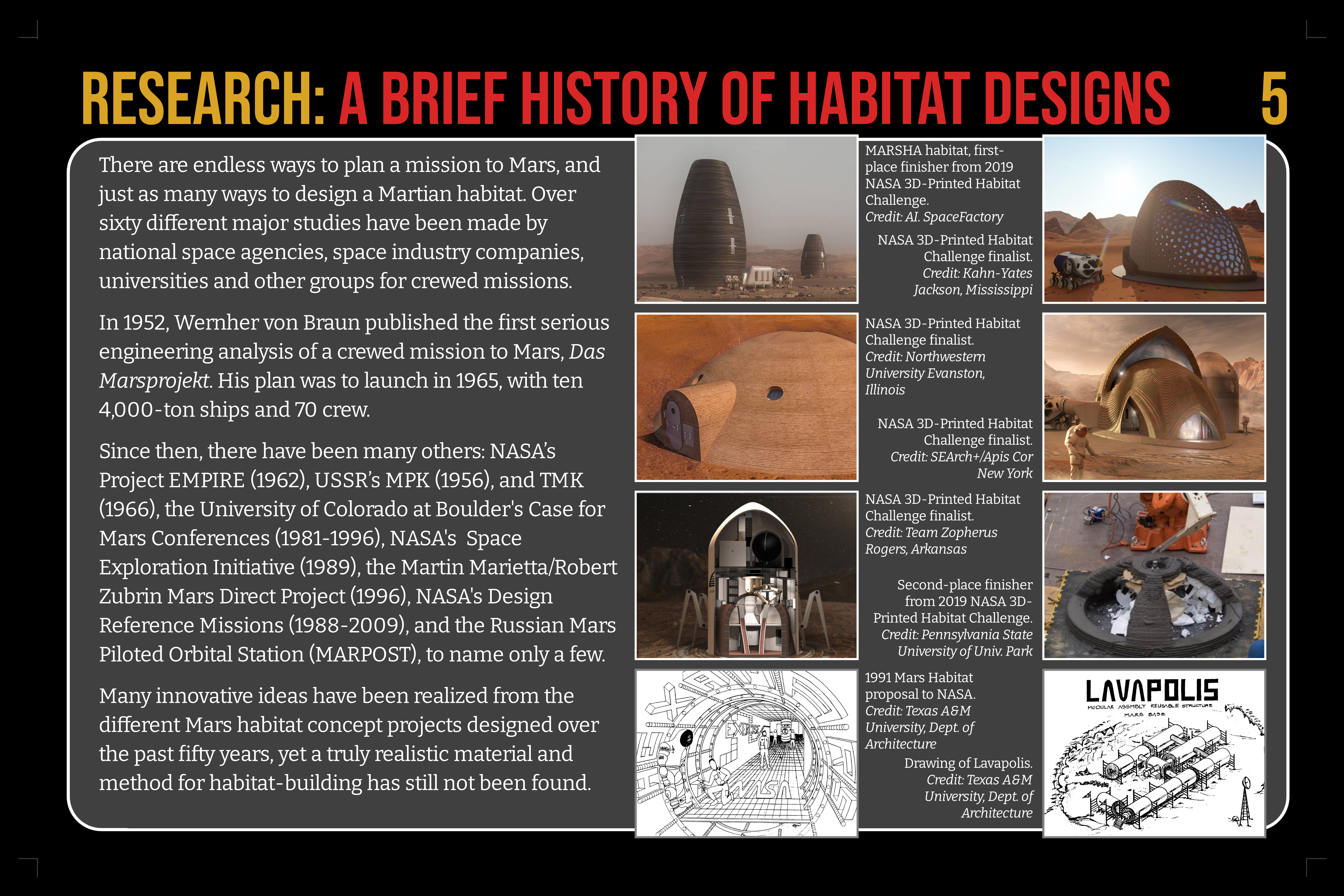

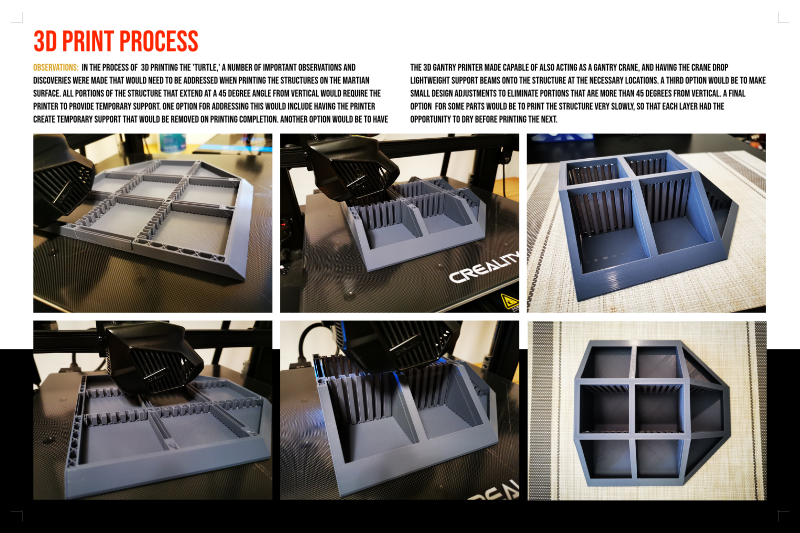

More recently, the explosion of 3D printing has inspired the possibility of printing structures on Mars, using a mix made of excavated Martian soil, called regolith, a glue or binder brought from Earth, and other compounds to make a Martian 'concrete' that would ooze out of a large, rolling printer with a pump and nozzle.

I thought that the 3D printer option was a really great one, but looking at recent experiments from a NASA competition to see if 3D printing on Mars was realistically possible, I saw real problems with the idea. To start, a huge amount of regolith would need to be excavated and collected in a giant mixer. This means we would have to send heavy, robotic construction equipment to Mars, and we would still need to send a huge amount of the glue and other chemicals, to mix with the regolith. In fact, it's estimated that 95 percent or more of the concrete's materials would still have to be carried to Mars, and these would be extremely heavy.

We would also need to send powerful pumps, pipes and other equipment, that would all require a large amount of electrical power, and that would all be extremely heavy, too. To top it all off, the printed structure would still not be very airtight or warm.

my solution – 3d-printed foam

That's when I had the idea to use something that I've seen my dad use in his construction work – foam! When we build houses on Earth, we use insulation foam to seal openings. This foam comes in compressed cans, like spray paint cans, for small projects, and in compressed tanks, like scuba tanks, that are attached by a tube to a spray gun, for large projects.

This foam expands as it comes out of the can and it dries really quickly. When it's dry, it's almost as hard as a rock, even though it is so lightweight that an entire wall of it could easily be lifted by one person, here on Earth. On Mars, it would only weigh 40 percent of that. A few astronauts could probably move a whole foam house if they had to.

The foam is also a great thermal insulator. That's what it's used for in construction on Earth. Finally, it sprays from a nozzle a lot like plastic filament comes out of a 3D printer.

Obviously, we wouldn't be able to use the exact same insulation foam that you'd get at the hardware store. A specially formulated version would need to be chemically engineered into an airtight radiation-resistant expanding foam, or ARREF, for short!

the structure of my habitat…

With living needs and a building material decided, I had to think about the shape of my structure. My first shape was a cylinder, standing on one end, with a dome on top, that I called the Tower.

It didn't take long to realize that it didn't make much sense for the structure to be more than one story tall, and it's not like there's too little space left on Mars. High winds and sandstorms would make having a multi-story building illogical, and staircases are hard to build and are a waste of interior space.

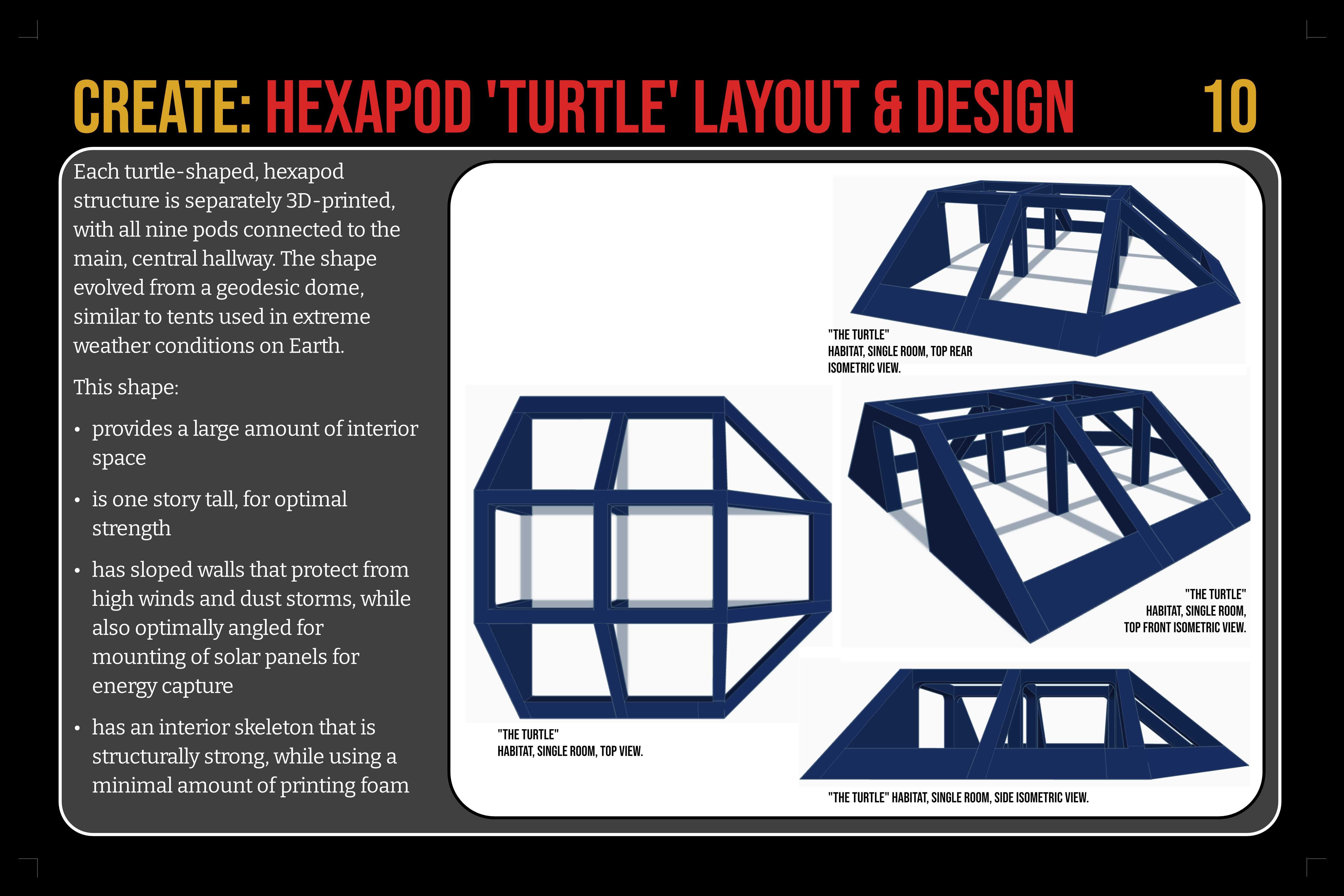

I then chose an octogonal shape that had slanted walls to reduce wind and sand storm damage. I called this design the Mars 8. The slanted walls would make great surfaces for mounting solar panels that would face in multiple directions for optimal energy capture. When I started to model this design, I realized that having eight sides would take away a lot of interior space, but, reducing the sides to six – from an octagon to a hexagon – the benefits remained, while making a larger interior space, a stronger structural frame, and an easier design to print. I called this design the Elezering 6.

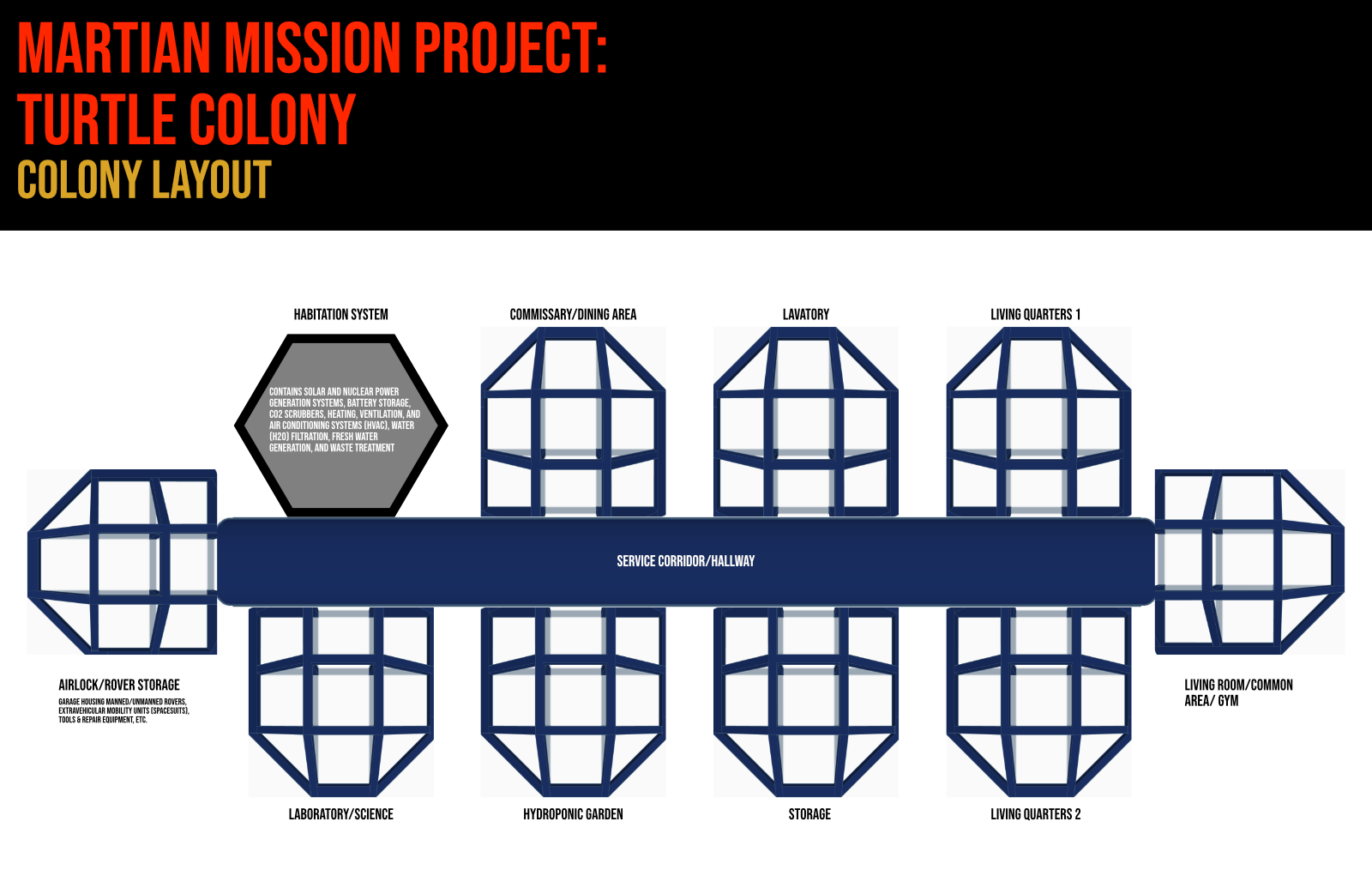

I knew that the Mars base would need many connected Elezerings, and I decided that the easiest and most practical way to connect the structures would be with one, long central corridor, like a hallway. However, when I tried to connect the separate Elezerings to the corridor, I realized that I would need to redesign one side of the Elezering to make a hatchway possible.

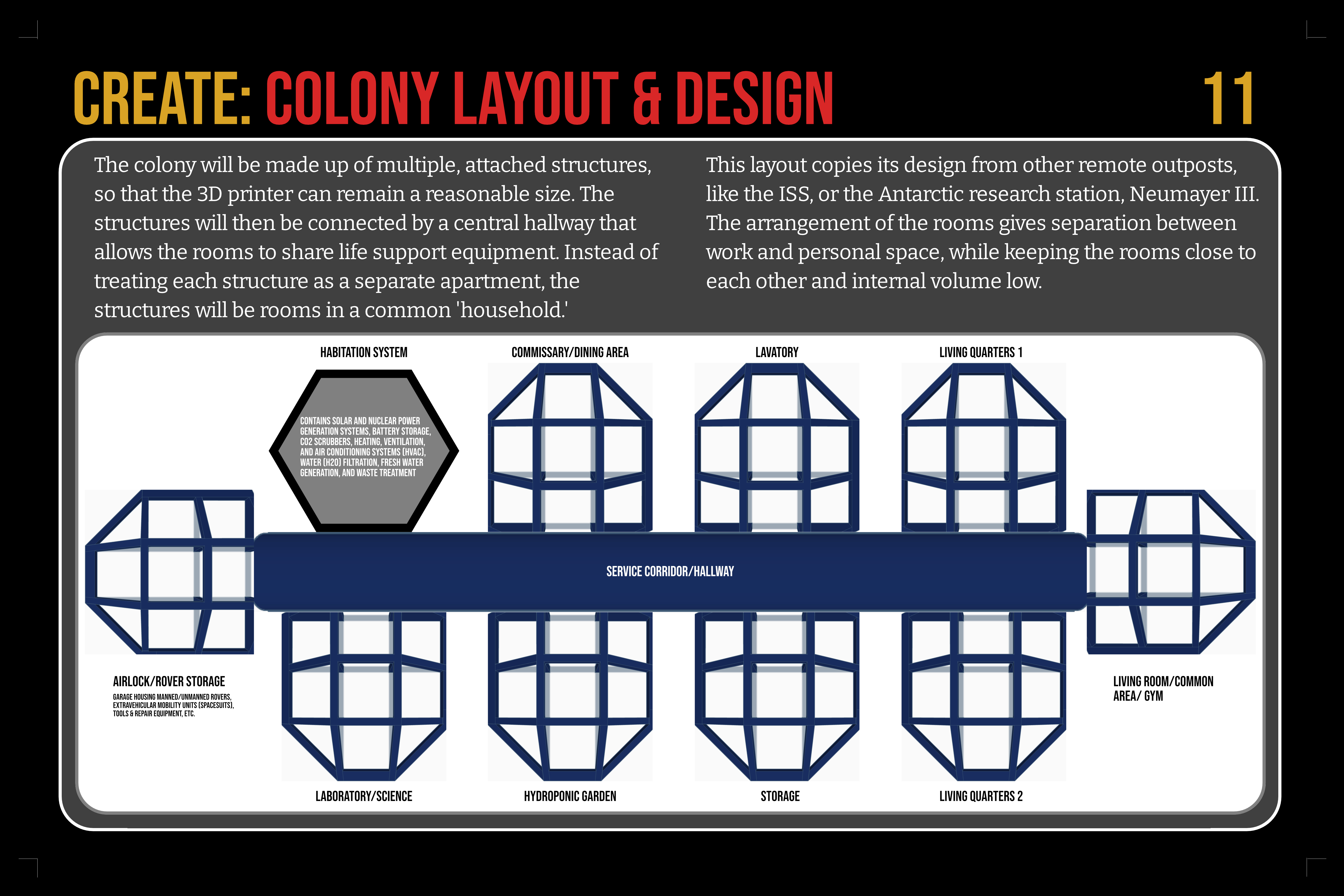

The final design is a six-sided, turtle-shaped structure that I obviously decided to call the Martian Turtle. This design keeps all of the benefits of the Elezering shape, while connecting to a shared corridor that brings life-sustaining services to each turtle.

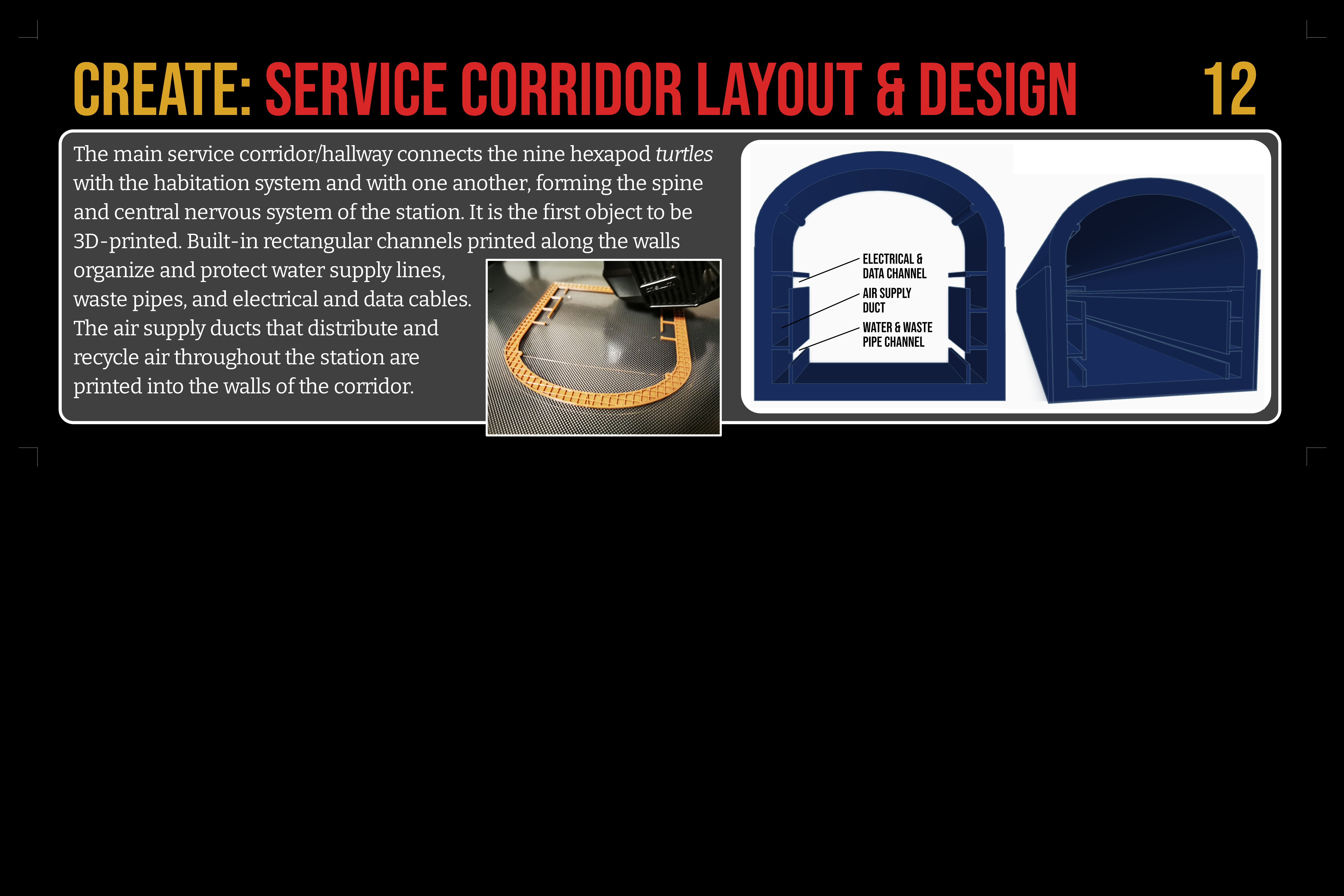

The corridor is 3D-printed with built-in rectangular channels to organize and hold water lines, waste pipes, electrical and data cables, and with ducts to distribute and recycle air throughout the station.

Each of the nine turtles has a different purpose, including a kitchen/dining room, a bathroom, two bedrooms (for six inhabitants), a storage room, an indoor, hydroponic garden, a mechanical room, and even a garage for the rovers and an airlock to the outside.

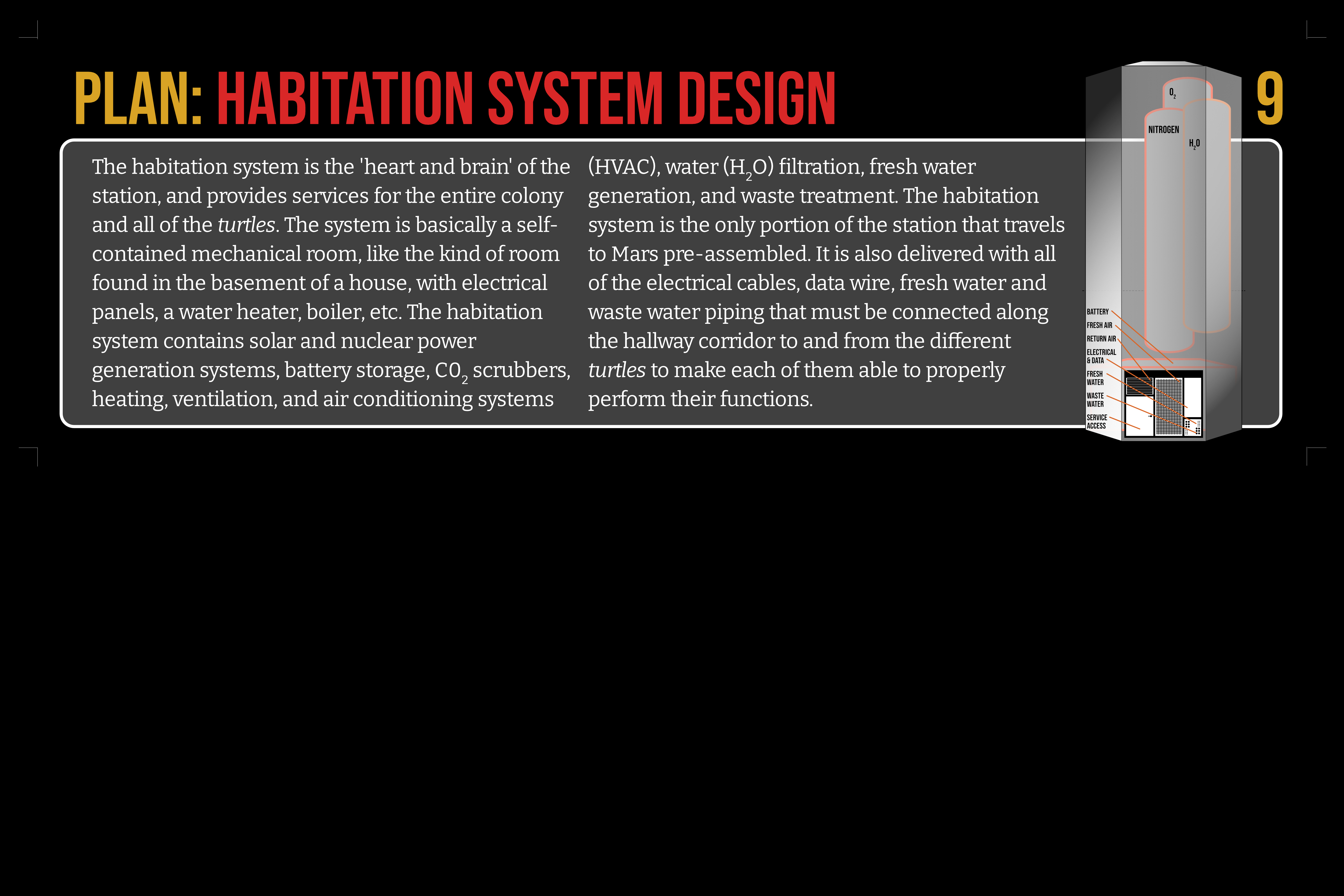

The final major part to consider was the life-support, or habitation system. The habitation system is the 'brains' of the station, and provides services for the entire colony and all of the turtles. The system is basically a self-contained mechanical room, like the kind of room found in the basement of a house, with electrical panels, a water heater, boiler, etc. The habitation system contains solar and nuclear power generation systems, battery storage, C02 scrubbers, heating, ventilation, and air conditioning systems (HVAC), water (H2O) filtration, fresh water generation, and waste treatment.

The habitation system is the only portion of the station that travels to Mars pre-assembled. It is also delivered with all of the electrical cables, data wire, fresh water and waste water piping that must be connected along the hallway corridor to and from the different turtles to make each of them able to properly perform their functions.

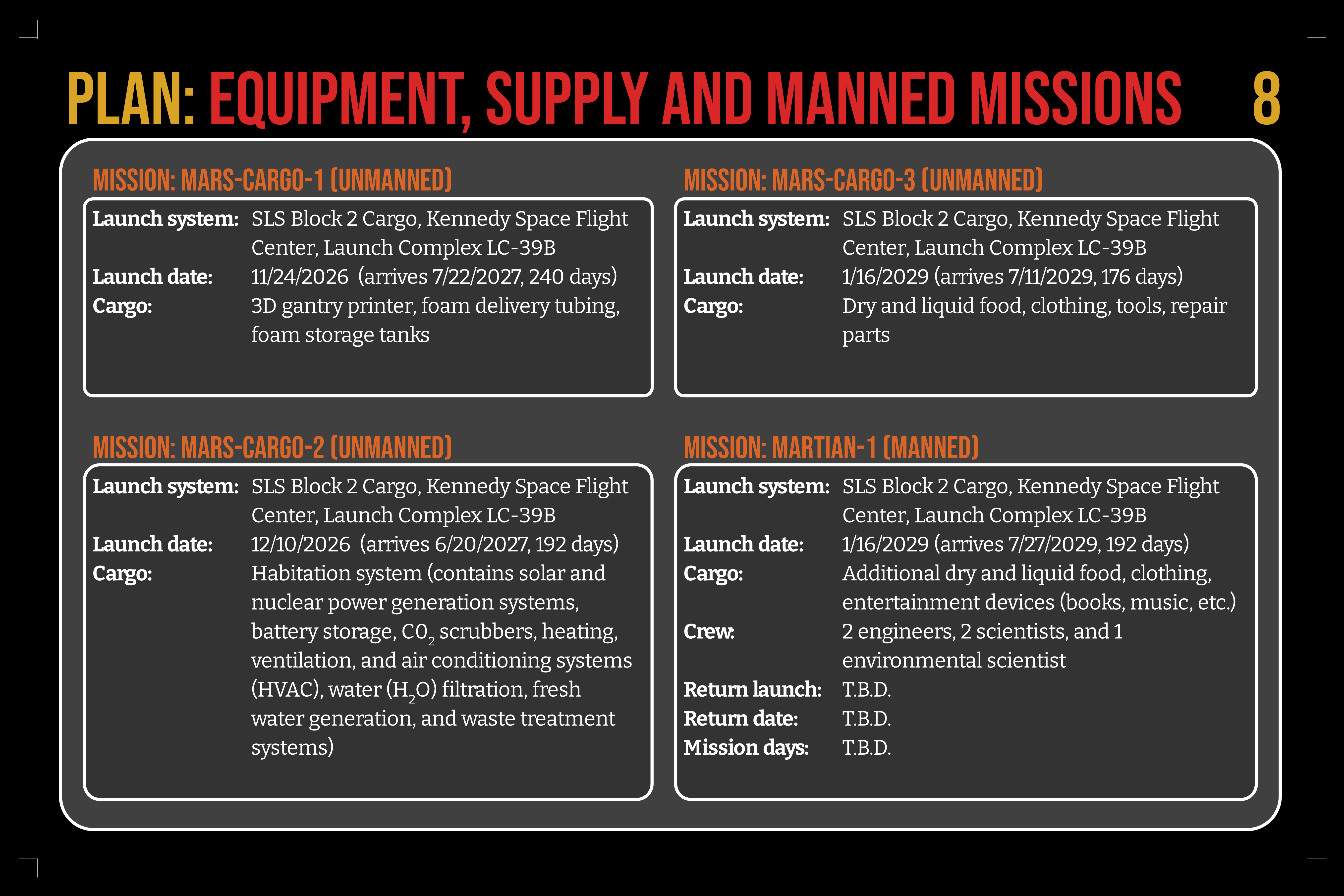

With all of the materials chosen and the design completed, building my habitat on Mars only requires figuring out when to send each load of materials, before humans make the trip to their new home. There are very limited windows of time where Earth and Mars are closely aligned for a quick, seven-month trip. According to NASA's online trajectory tools, there are flight windows available in 2024, 26, 28 and 29. By my calculations, we can send two equipment flights in 2026, and then send supply and human flights in 2029 for a successful Mars mission.